Feb 21, 2014 - Installing a Fahrenheat FUH54 Electric Garage Heater

The Old Heater

I bought this 4000W Cadet "Hot One" heater shortly after we finished

building our garage in 2001. It was really undersized for my 24'x28'

garage, but once I closed off the attic space with a new stairwell, it

could keep the garage in the mid 60's while I worked. I only used it a

few times a year when I was working out in the garage, so it lasted me

more than 12 years.

I would blow the dust out of it every now and then with the shop vac,

but did have to take it apart and lubricate the fan at one point. In

recent years the fan bearings were getting really noisy, so when the

thermostat quit working recently, I decided it was time to buy a new

heater.

Preparing the Wiring

After a little research, I chose a new

Fahrenheat FUH54 garage heater. At 5000 watts, it is still

undersized for my 24' x 28' garage, but it will provide more heat than

my old heater did.

Fahrenheat makes a 7500 watt model also, but I would have had to run

new wiring for that one. The existing wiring already had 10/3 cable, so

the FUH54 was the obvious choice. I did have to replace the existing

breaker with a new 30amp breaker.

The Cadet heater sat on the floor, and I had a receptacle it plugged

into next to my attic stairs. To keep things simple, I mounted a new

box up near the ceiling and fished a short piece of 10/3 cable between

the old and new boxes.

Garage Wiring Finished

After reading several reviews, I decided to use a clothes dryer cord to

connect the heater. It is affordable, readily available, and lets me

take the heater down easily for cleaning or maintenance.

To keep the installation tidy, I mounted a dryer receptacle in the new

box up near the ceiling. Then I installed a heavy duty 30A switch in

the old receptacle box near the floor.

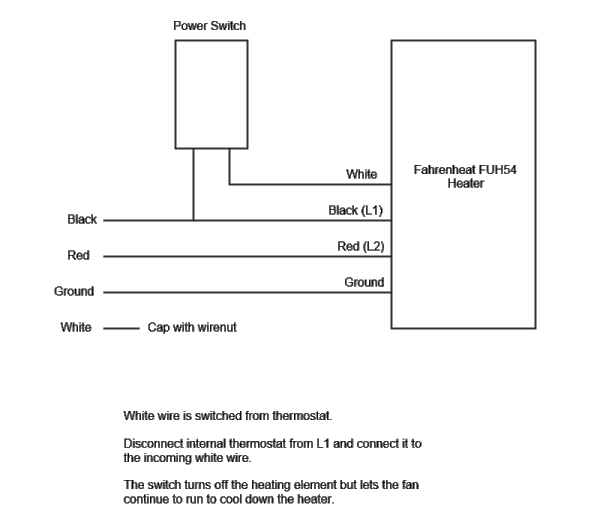

Rewiring the Thermostat

While I can reach the thermostat on the heater by standing on the lower

step, I thought a switch on the wall would be more convenient for

turning the heater on and off. I was originally going to install a line

voltage thermostat, but when I got to the store I saw they had large

openings at the top and bottom. I figured that was just one more thing

to collect dust. Once the thermostat is set, all I really need to do is

turn the heat on and off. The switch works fine for that, it was half

the cost, and I don't have to worry about dust getting in it.

The FUH54 heater is designed so the fan keeps running after it is

turned off to cool off the heating element. I kept this feature by

turning the unused white wire into a switched lead for the element. The

fan is still wired full time to keep the original cooling feature.

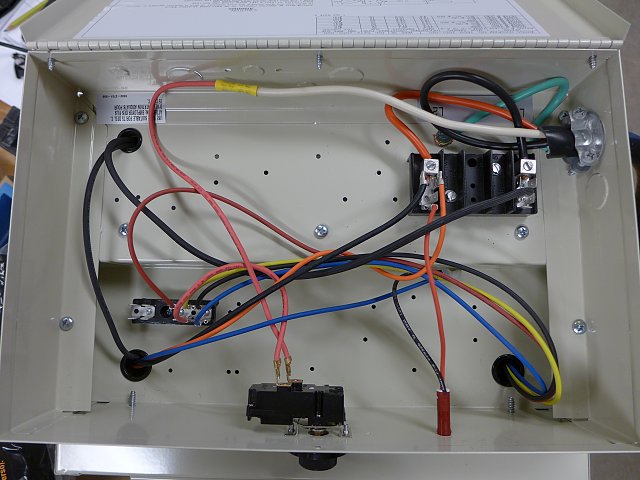

Rewiring the Heater

Inside the heater, I lifted the thermostat wire that connected to L1,

and connected it to the new switched white wire.

I needed a 3/4" cable clamp to accommodate the dryer cable, but the

FUH54 only has one 3/4" knockout on the left side. That puts the

incoming cable rather close to the terminal block, but it still works

out OK.

The Installed Heater (Temporarily)

I located the ceiling joist, and mounted the heater bracket to the

ceiling with the supplied lag bolts. Then it was easy to lift the

heater up, hook it into the bracket slots, and secure the bolts.

Finally, I have heat again!

The Cord Issue

Because the FUH54 only had a 3/4" knockout on the left, it meant the

cord had to loop around the back of the heater to reach the outlet on

the right. It worked fine, but visually it drove me crazy.

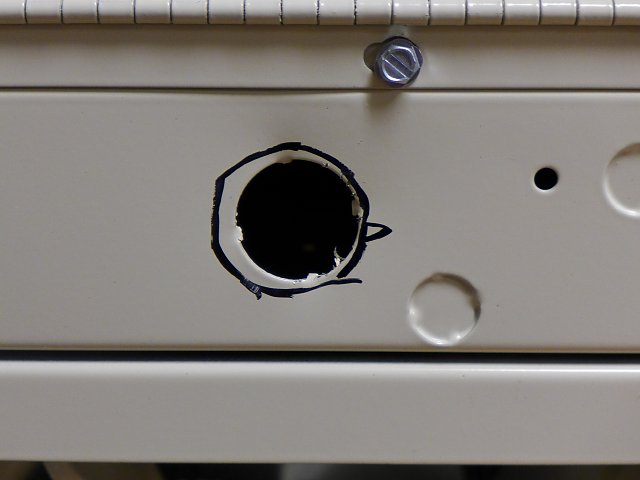

Relocating The Power Cord

I decided to move the power cord to the back of the heater, to one of

the knockouts in the center. Unfortunately, that was only 1/2" and I

needed 3/4".

Enlarging the Knockout

Ideally, I would have preferred to use a knockout punch to make the

hole bigger. But I wasn't going to spend $40-60 on a punch I'm probably

never going to use again. A step drill might have worked, but those

were almost as expensive. Filing and hole saws seemed like too much

work, and I was worried about metal shavings falling into the

heater.

Thankfully, I had a metal nibbler that worked great for enlarging the

knockout hole. I have had my nibbler for over 25 years since my days

working with electronics, but I see they are still available today from

Amazon.com.

Reinstalling the Cord

The nibbler leaves a fairly jagged hole, but once the cable clamp is

mounted you can't tell it's not a factory knockout.

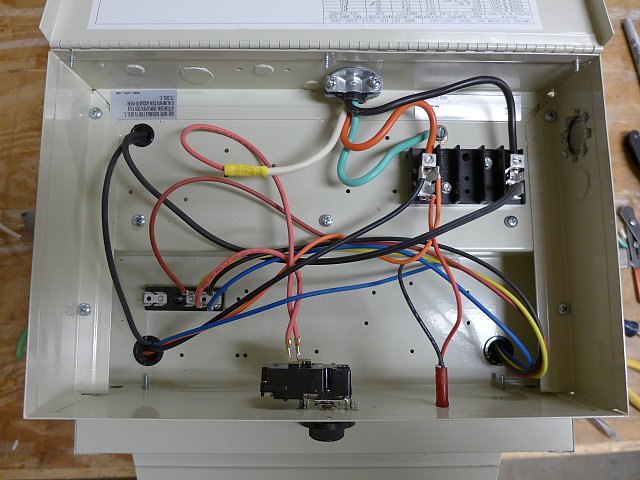

Rewiring the New Cord

Once the new cord was installed, I could make all the connections.

Moving the cord to the back middle also eliminated the crowding around

the terminal block.

Remounting the Heater

With the wiring completed, it was a simple matter of hooking the heater

back on the bracket and plugging in the cord.

Finished!

The shorter cord in the back makes for a much neater installation. I am

just happy to have heat again.