When we built our garage back in 2001, I installed four fluorescent

lights on the ceiling of our garage. They were all I could afford at the

time, and were a huge improvement over the single light bulb in my

previous work shed. Overall I have been happy with the original lights,

but they have been getting dimmer over the last 15 years. Several areas

of the shop were still quite dark, especially in the back corners.

Recently, my wife was working out in the shop with me and was straining

to see her work in one of the back corners. So I decided it was time to

upgrade my shop lighting.

Making the Connection

Each light has a knockout on each end that allows the wiring to be run

through the light fixtures. To join the lights and protect the wiring

from the sharp metal edges, I used 'close' pipe nipples with a nut and

plastic bushing on each side.

Finishing The Upgrade

There's really not much to the light

installation. I simply unscrewed the old light fixtures, then snapped a

chalk line on the ceiling so the lights would end up straight. Then I

screwed the new fixtures to the ceiling and made up all the electrical

connections. It only took me a few hours in the afternoon to do the full

upgrade.

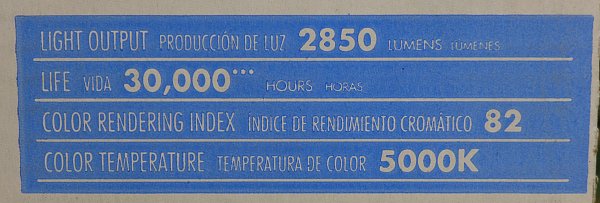

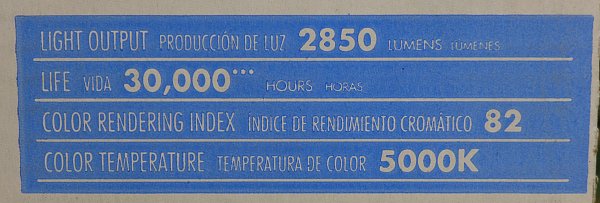

I debated whether to use 'warm' (3000K) bulbs or 'daylight' (6000K) bulbs

in my light upgrade, but settled on 'natural' bulbs (5000K). They provide a

nice white light without the blue tint that tends to come with daylight

bulbs. They cost slightly more and are harder to find, but I am very happy

with the color of the lighting. Best of all, the shop is now well lit with

no shadows or dark corners.